A lot of people come to me asking what the best steel for knives is and the answer I tell them is that I don’t know. That’s because the purpose of every knife is different and the onus lies on the owner to decide whether the material used in his knife is the right one or not.

There are knives that have an extremely sharp edge while others are super-resistant to corrosion and there are others out there that are the perfect tool for prying. The reason why they’re also so different has a lot to do with the steel.

Normally steel alloy is used for making knives and the difference in the composition of the alloy determines the real intention of that blade. For example, a fighting knife will have a totally different alloy composition as compared to a survival knife and thus, it’s the purpose of the knife that decides which steel is the best for any particular design.

There are 5 factors that a knife maker looks at while choosing an alloy and the steel:

- ability to take an edge

- ability to hold an edge

- toughness of the alloy

- strength of the alloy

- corrosion resistance

The Ability to take an Edge:

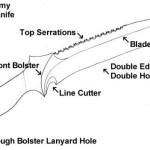

The sharpness of a knife is defined by its ability to take and edge and plays a key role in the shape and functionality of the knife. The sharpness, though, is also due to the angle of the blade grind and due to the construction of the blade.

The Ability to hold and Edge:

This basically means the amount of time it takes before a knife that has been in use can be sharpened again. I own a lot of knives so I know how many times I keep sharpening them and one thing I’ve noticed is that the longer the knife takes to sharpen, the longer it will hold its edge!

Toughness of the Steel:

I’m sure you’ve seen a lot of knives being worn and chipped due to high usage and basically, the toughness of the steel is a measure of the metal’s ability to resist wear and tear. A lot of people confuse toughness with strength; the strength of a knife means its resilience to deformation on high pressure usage.

Strength of the Steel:

I’ve already defined strength above so won’t bother repeating myself; however one key point to note is that toughness and strength are inversely proportional to each other.

This means that stronger steel will tend to wear out more quickly and while this rule is not universal; it’s pretty true in most cases and out of personal experience.

Corrosion Resistance:

Corrosion resistance is a measure of the steel’s ability to resist rust and stains.

Apart from focusing on the 5 factors mentioned above, knife makers across the world also use certain other treatments in order to improve the finish and performance of the knife steel. For example, one common usage among knife makers is to apply oxidation technique on the steel in order to improves it’s resistance to corrosion.

Types of Steel used in Survival Knives:

These days, knife manufacturers use different types of steels to produce high quality survival knives. However, all of them broadly fall under 3 main categories which are tool steel, stainless steel or carbon steel. I’ll explain each one of them in detail below for your benefit.

Tool steel is one of the most widely used steel for making average quality survival knives. Although it’s not as popular as stainless steel, a lot of knife makers still use it to this day for cost-effective reasons.

The most popular type of steel that is used in the manufacture of knives these days is stainless steel. Not only does it give a high quality finish, it is also extremely corrosion resistant if taken good care of. Normally, knife makers use a chromium content of 13% while making blades with stainless steel to improve its resistance to rust.

The 3rd type of steel that is widely used for knife manufacture is carbon steel which is very popular with people who need a durable knife. I personally love knives with carbon steel because not only are they easy to sharpen, they’re extremely tough and durable as well. The only downside with using carbon steel is that the chance of rust formation is quite high.

Well, that’s all about the steel that’s used in knives these days. In case you’re still wondering “What’s the best steel for knives”, then the answer, my friend, is that it all depends on you! My personal suggestion would be to not dwell so much on this matter and rather, you should look at other people’s reviews before buying such knives online. I always look at the reviews on Amazon before choosing a good survival knife for myself.

{ 1 comment }

The best survival knives have a full tang for maximum strength.

Familiarize yourself with a little more about the tools prior to making a decision.

Pocket Knives are the most valuable and versatile tools,

that help you to do certain jobs from opening boxes,

letters, packages, and even you can use it for self defense.

Comments on this entry are closed.

{ 1 trackback }